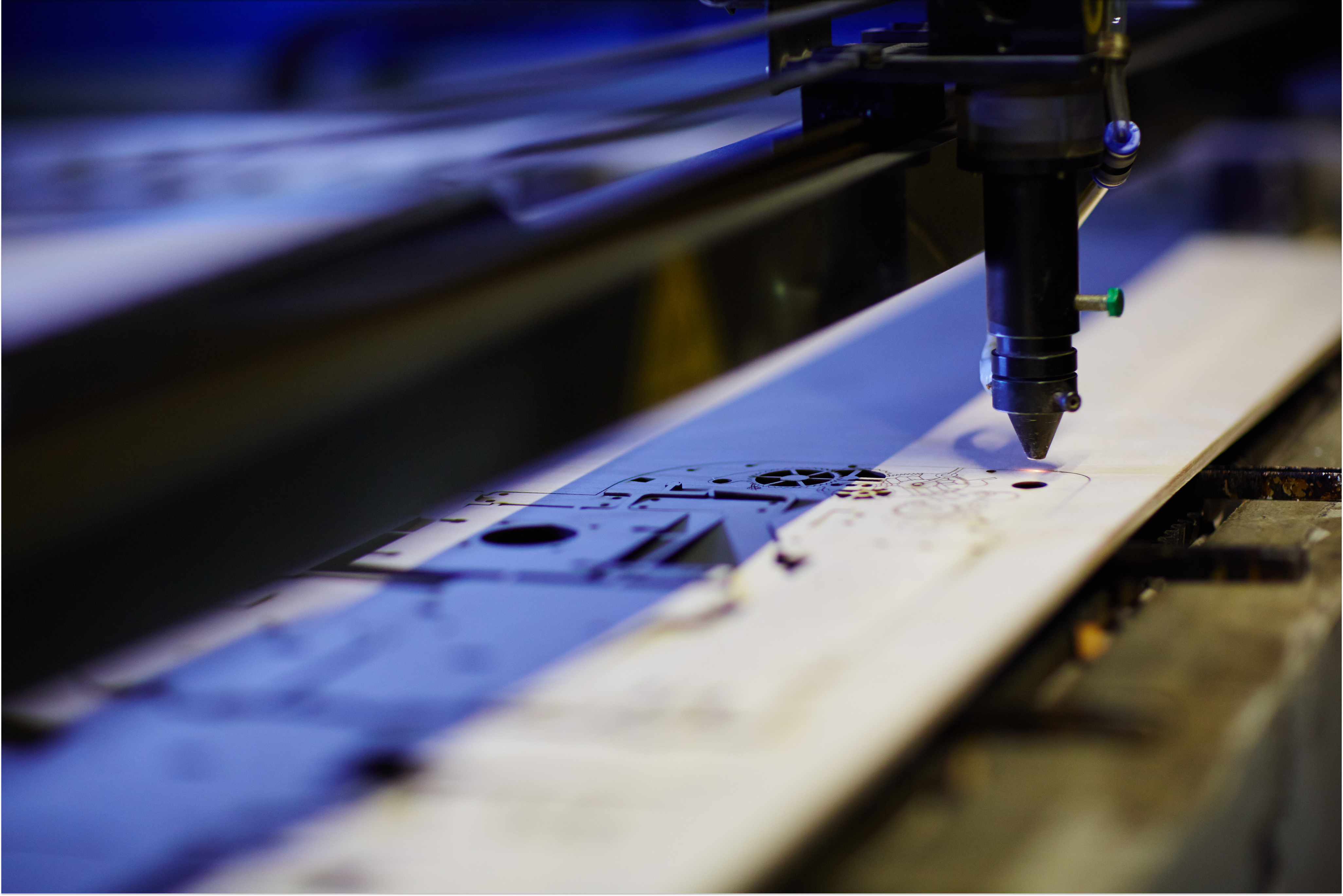

CNC Laser Cutting

A CNC laser cutter is a piece of computer numerical

control (CNC) equipment that uses a focused, high-powered laser beam to mark, cut, or

engrave a material to form custom shapes. Its unique design and operation make it highly

accurate, especially when cutting intricate shapes and small holes.

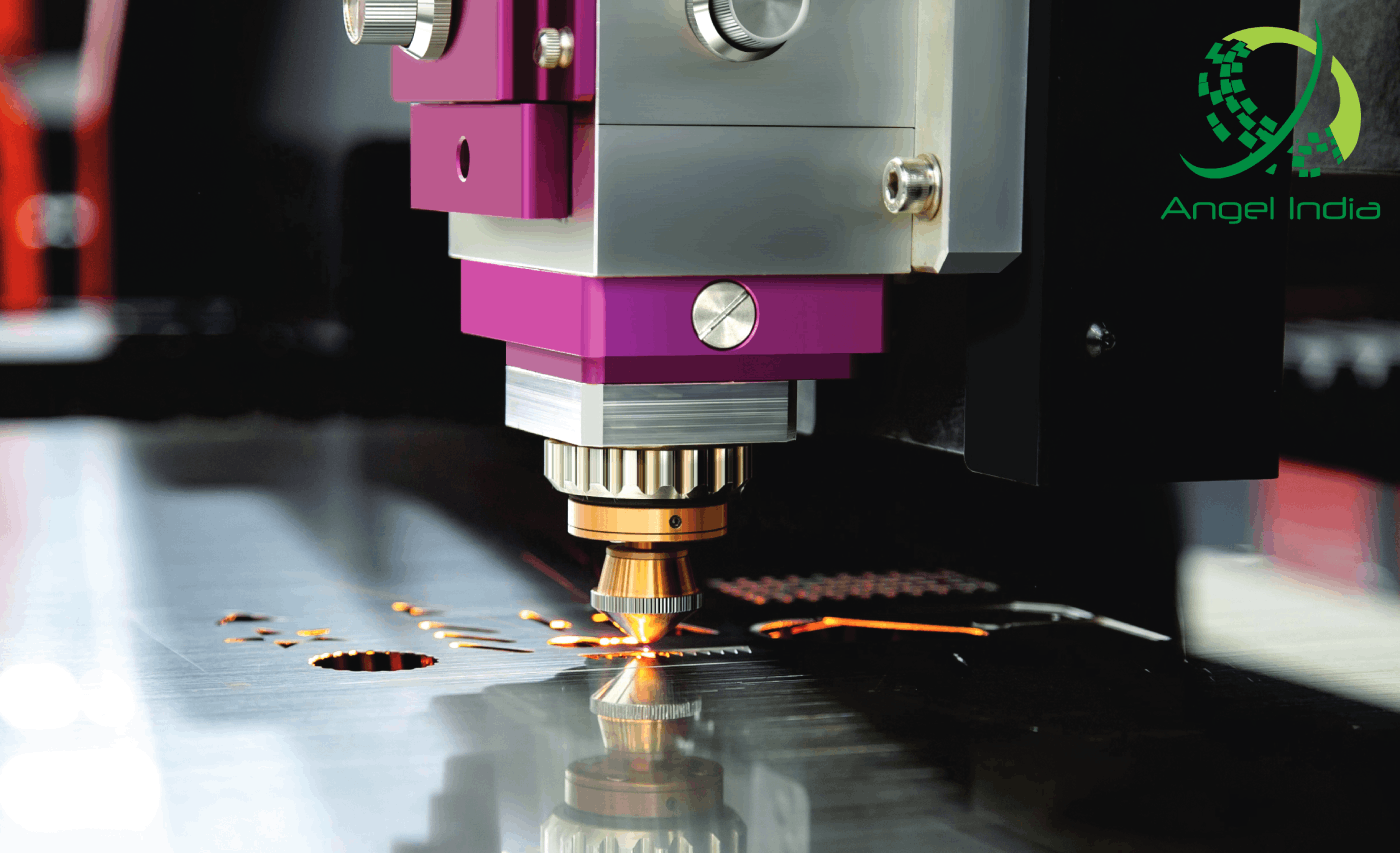

We have complete allegiance in offering highly demanded CNC Laser Cutting Services. We are

providing most efficient services to machinery manufacturing industry, where precision and

smooth finish of a workpiece is the utmost priority. Thereby, we have developed a state of

art infrastructure, which is fully equipped with CNC based machine for cutting steel and

other materials. Further, we are leveraging the laser cutting techniques for providing the

provision of customization in terms of design, thickness and size of the workpiece.